Polyethylene Terephthalate (PET) is a polymer material widely used in Encasement, Electronics, Medical and other fields. PET film has excellent Mechanical Properties, Chemical Stability and Transparency, making it an ideal substrate for a variety of coating applications. This article will introduce the application, methods and related technologies of PET film in detail, aiming to provide reference for research and production in related fields.

1.1 Field of Encasement

In the field of Encasement, PET films are often used as Encasement materials for food, medicine and cosmetics due to their excellent barrier properties and Mechanical Properties. By applying specific coatings on the surface of PET films, its barrier performance, anti-corrosion performance and antibacterial performance can be further improved. For example, by applying a layer of aluminum oxide or silicon dioxide Nano coating, the oxygen and moisture resistance of PET films can be significantly improved, thereby extending the shelf life of the items in Encasement.

1.2 The field of electronics

The application of PET film in the electronic field is mainly reflected in flexible electronic devices and display screen protective films. By coating conductive polymers or metal nanoparticles on the surface of PET film, flexible transparent conductive films can be prepared, which are widely used in Touchscreen, electroluminescent displays and solar cells. In addition, PET film can also improve the display effect and durability of the display screen by applying anti-reflection coatings and anti-fingerprint coatings.

1.3 Medical field

In the medical field, PET films are often used as substrates for drug controlled release films and Biosensors. Sustained release and targeted delivery of drugs can be achieved by coating drugs or biologically active substances on the surface of PET films. In addition, PET films can also be used to make disposable medical apparatus and protective supplies by coating antibacterial coatings.

Second, the method of PET film

2.1 Solution Spreader Method

Spreader method is a common film method, suitable for various coating materials. The specific steps are as follows:

Preparative Spreader Liquid: The coating material is dissolved or dispersed in a solvent to prepare a uniform Spreader Liquid.

Spreader: Spreader liquid uniformly coated on the surface of PET film, commonly used Spreader methods are spin coating, dip coating and scratch coating.

Drying and curing: Spreader PET film drying and curing treatment, so that the coating material and the substrate firmly bonded.

The advantages of solution Spreader method are simple operation, low cost, and suitable for large area Spreader. The disadvantage is that the selection and treatment of solvent is more complicated, and the thickness and uniformity of coating are limited by Spreader process.

2.2 Physical vapor deposition (VD) (PVD)

Physical vapor deposition (VD) is a film technology carried out under high vacuum, mainly including evaporation deposition and sputter deposition.

Evaporation deposition: The coating material is heated and evaporated into a gaseous state, and the gaseous molecules condense on the surface of the PET film to form a coating.

Sputtering deposition: bombarding the coating material with high-energy particles in a vacuum chamber, so that atoms or molecules are sputtered onto the surface of the PET film to form a coating.

The advantages of the PVD method are that the coating is dense, strong adhesion, and suitable for high melting point and difficult to dissolve materials. The disadvantage is that the equipment is complex and the cost is high, which is suitable for high value-added coating applications.

2.3 Chemical vapor deposition (VD) (CVD)

Chemical vapor deposition (VD) is a technique for forming coatings by chemical reactions at high temperatures. The specific steps are as follows:

Gas supply: The gaseous precursor of the coating material is introduced into the reaction chamber.

Chemical reaction: Under the action of high temperature and catalyst, the precursor chemically reacts to form a solid coating, which is deposited on the surface of the PET film.

Post-processing: carry out necessary post-processing, such as annealing and cleaning.

The advantage of the CVD method is that it can prepare high purity and high density coatings, which is suitable for preparing various functional coatings. The disadvantage is that the process is complicated, the cost is high, and the high temperature treatment may affect the PET substrate.

2.4 lame plating

Lame plating is a film technique that sprays Spreader liquid onto the surface of PET film by Nozzle. The specific steps are as follows:

Preparative Spreader Liquid: The coating material is formulated into a Spreader Liquid of appropriate viscosity.

Lame plating: Spray the Spreader evenly onto the surface of the PET film using Nozzle.

Drying and curing: Spreader PET film drying and curing treatment.

The advantage of lame plating is that it is suitable for large-area and complex shape Spreaders, and the Coating thickness is adjustable. The disadvantage is that the Spreader process is prone to splashing and uneven coating.

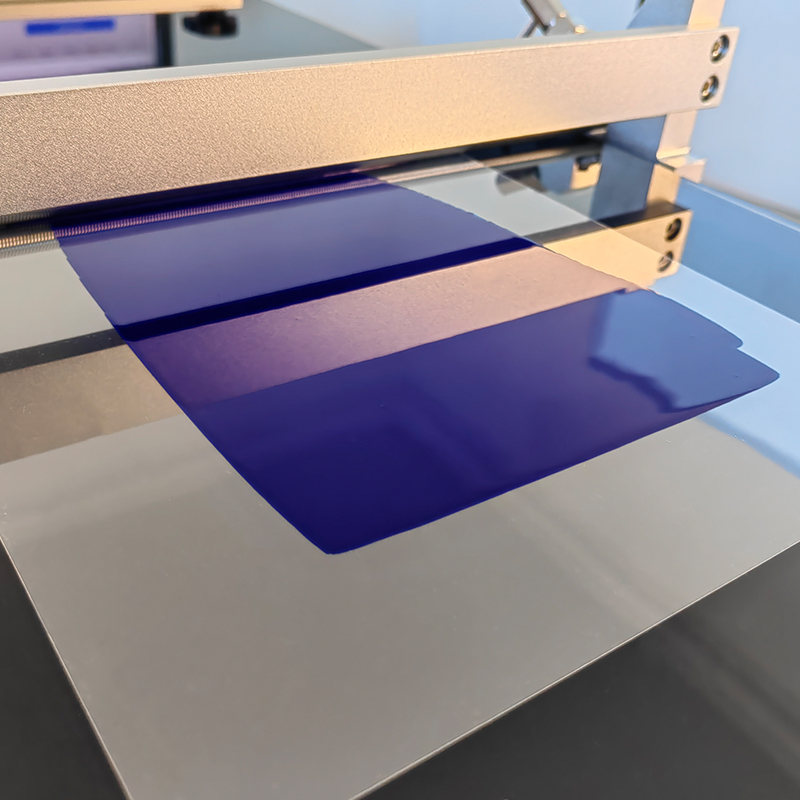

2.5 roller painting

Roller painting is a kind of film technology in which Spreader liquid is applied to the surface of PET film by roller. The specific steps are as follows:

Preparative Spreader Liquid: The coating material is formulated into a Spreader Liquid of appropriate viscosity.

Roller painting: Spreader liquid is evenly applied to the swirling/spinning roller, and then the Spreader liquid is transferred to the surface of the PET film through the roller.

Drying and curing: Spreader PET film drying and curing treatment.

The advantages of the roller painting method are that the Spreader is fast and efficient, which is suitable for large-scale production. The disadvantage is that the equipment investment is high, and the Coating thickness and uniformity are limited by the roller painting process.

3.1 Coating thickness

Coating thickness is a key parameter affecting coating performance. Coating thickness is too thin may lead to incomplete realization of coating function. Coating thickness is too thick may affect the adhesion and Mechanical Properties of coatings. Common Coating thickness Measuring methods include Microscope method, optical interference method and X-Rays fluorescence method.

3.2 uniformity of coating

Coating uniformity directly affects the performance and Appearance of coatings. Commonly used methods for evaluating coating uniformity include Surface Profile Gauge measurement and Optical Microscopy observation.

3.3 coating adhesion

Coating adhesion refers to the bonding force between the coating and the PET substrate, which affects the durability and Stability of the coating. Commonly used coating adhesion test methods include cross-cut method, drawing method and disbonding method.

3.4 Hardness of coatings

Coating Hardness refers to the Hardness of the coating material, which affects the Abrasion Resistance and scratch resistance performance of the coating. Commonly used coating hardness testing methods include hardness gauge method and nano-Che method.

4.1 Anti-reflection coating on PET film

Anti-reflection coatings can reduce light reflection and improve light transmittance. The specific steps are as follows:

Preparative Spreader Liquid: Silica nanoparticles are dispersed in a solvent to prepare a uniform Spreader Liquid.

Spin coating: Spreader droplets are added to the swirl/spin PET film, and the Spreader liquid is uniformly Spreader on the surface of the film by centrifugal force.

Drying and curing: Spreader film is dried in the oven and cured at high temperature.

The results show that the light transmitance of the PET film coated with anti-reflection coating is significantly improved, which is suitable for the fields of display screen protective film and solar cell.

4.2 PET film coated with conductive coatings

Conductive coatings can impart conductivity to PET films, which are widely used in flexible electronic devices. The specific steps are as follows:

Preparative Spreader Liquid: A conductive polymer (such as polyaniline or polythiophene) or metal nanoparticles (such as silver nanowires or carbon nanotubes) are dispersed in a solvent to prepare a uniform Spreader Liquid.

Lame plating: Use Nozzle to evenly spray the Spreader liquid onto the surface of the PET film to form a conductive coating.

Drying and curing: Spreader film drying and curing treatment, so that the conductive material and the substrate firmly bonded.

By applying a conductive coating, the surface resistance of the PET film is significantly reduced, and the conductivity is greatly improved, which is suitable for applications such as Touchscreen, Electroluminescent Display, and flexible solar cells.

4.3 Antibacterial coating on PET film

Antimicrobial coatings can give PET film antimicrobial performance, suitable for medical and food Encasement fields. The specific steps are as follows:

Preparative Spreader Liquid: Antibacterial agents (such as silver nanoparticles or quaternary ammonium salts) are dispersed in a solvent to prepare a uniform Spreader Liquid.

Dip coating: immerse the PET film in the Spreader liquid, so that the Spreader liquid uniformly covers the surface of the film.

Drying and curing: Spreader the film in the oven drying, and the necessary curing treatment.

The results show that the PET film coated with antibacterial coating has a significant inhibitory effect on a variety of pathogens, and is suitable for the production of disposable medical apparatus, protective equipment and food Encasement materials.

5.1 Functional coatings

With the development of science and technology, the film technology of PET film is also constantly innovating and progressing. In the future, film technology will pay more attention to the functionalization and multi-functionality of coatings. For example, by introducing intelligent Response materials, multi-functional coatings such as Temperature Response, Humidity Response and Light Response can be prepared to expand the application range of PET films.

5.2 Environmentally friendly coatings

Environmental protection and sustainable development are important development directions of film technology in the future. Solvents and chemical Reagents used in traditional film processes may cause harm to the environment and health. In the future, green film technology will be widely used, such as aqueous Coating, bio-based Coating and solvent-free film technology.

5.3 High performance coatings

High-performance coatings refer to coatings with high mechanical strength, high Abrasion Resistance, high barrier and high conductivity. By introducing new materials and optimizing the film process, the performance of coatings can be significantly improved to meet the needs of high-end applications. For example, by introducing new materials such as graphene, carbon nanotubes and nano-metal particles, high-performance conductive coatings and high-barrier coatings can be prepared.

Due to its excellent performance and wide application prospects, PET film has important research value and application potential in the field of film technology. Through different film methods, various functional coatings can be applied on the surface of PET film to significantly improve its performance and expand its Applications. In the future, with the continuous emergence of New materials and new technologies, PET film technology will develop towards functionalization, environmental protection and high performance, and further promote the application of PET film in Encasement, Electronics, Medical and other fields.