Small coaters play an important role in the laboratory, providing researchers with a convenient Spreader platform. However, in order to ensure its normal operation and prolong its service life, daily maintenance work is essential. Here are some tips for care and maintenance of small coaters:

Small coaters generate waste and by-products during operation, and timely cleaning of these residues is the key to keeping the equipment clean. This avoids the interference caused by the accumulation of waste to the normal operation of the equipment, and also helps to ensure the Stability of the Spreader effect.

When cleaning the coater, avoid pouring water directly onto the countertop or using strong corrosion solvents and wire brushes to clean the countertop. These practices may cause corrosion and abrasion on the countertop, which in turn affects the service life of the coater. It is recommended to wipe with a soft cleaning cloth to protect the surface of the equipment.

Make sure that the film material used meets the mass requirements and matches the coater. Low mass or inappropriate film materials may cause damage to the coater or affect the film effect. Therefore, be careful when choosing film materials and ensure that they meet equipment specifications and requirements.

Once any malfunction or abnormal situation of the coater is found, it should be stopped immediately for inspection and consult after-sales technical support if necessary. Timely detection and treatment of problems can effectively reduce equipment damage and ensure the smooth progress of the experiment.

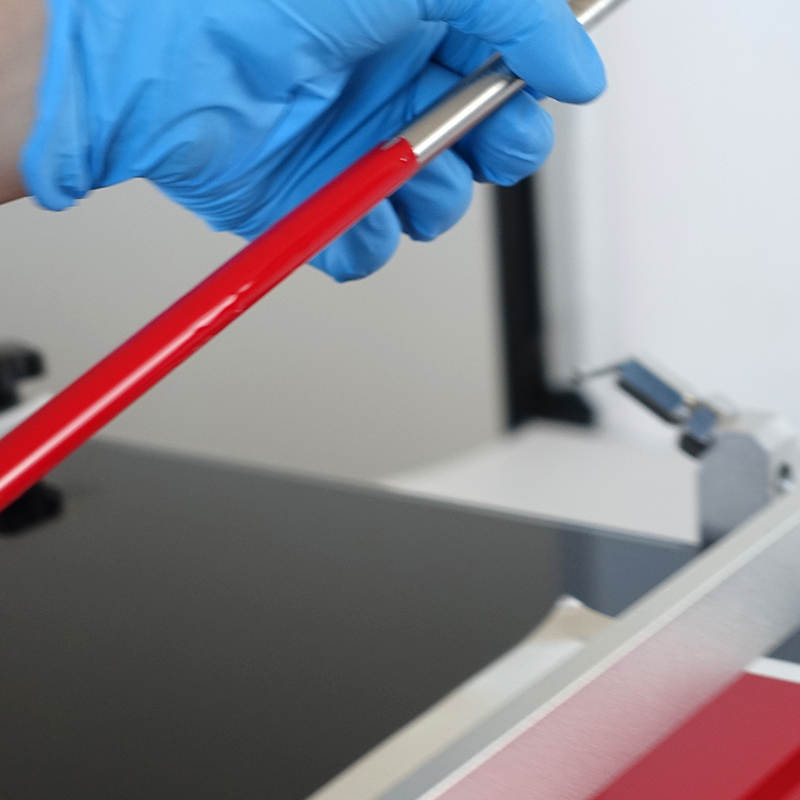

Regularly check the various components of the coater, including coating applicators, rollers, transmission systems, etc., to ensure that the equipment is not loose, abrasion or damaged. If abnormal conditions are found, they should be repaired or replaced in time to ensure the normal operation of the equipment.

When using the coater, be careful to handle the coating applicator with care to avoid abrasion caused by collision and affect the film effect. Careful use of the coating applicator can extend its service life while ensuring the Stability of the Spreader effect.

Through the above daily maintenance work, small coaters can be effectively protected, their service life can be extended, and the accuracy and Stability of experimental results can be ensured.