In scientific research laboratories, Film Applicator is a common experimental device used to perform Spreader experiments on various substrates to study the performance and application of different coatings. This article will introduce the Working Principles of Laboratory Film Applicator and its application in scientific research.

The Working Principle of the Laboratory Film Applicator is similar to the Film Applicator in industrial production, but usually has a smaller size and more flexible Operation mode to adapt to the needs of scientific research experiments. The main Working Principle includes the following key steps:

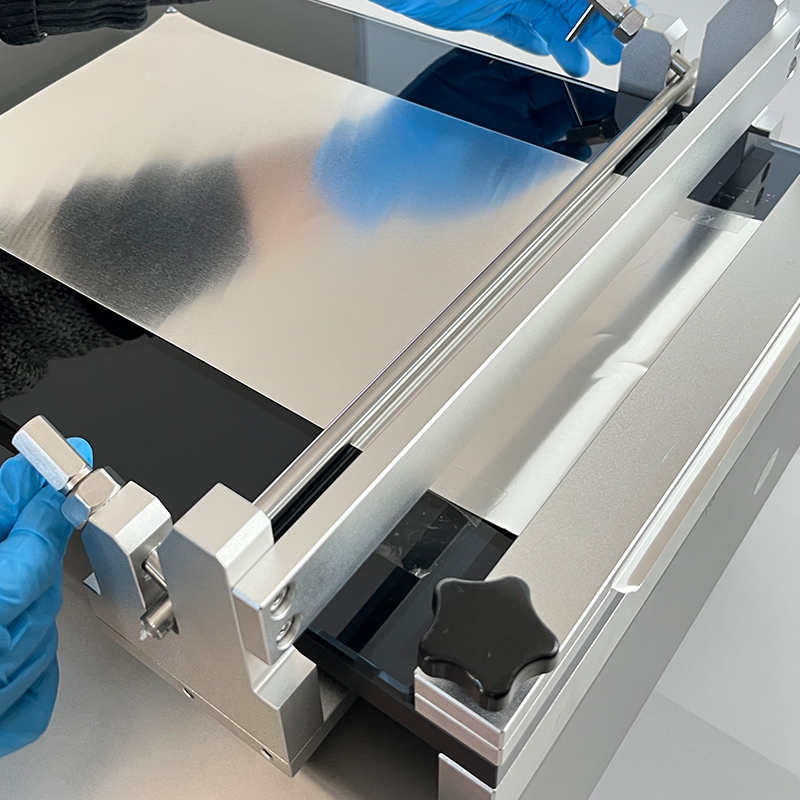

1) Before conducting the film experiment, you first need to prepare the Spreader material and substrate. Spreader materials can be various coatings, solutions or dispersions, while the substrate can be Glass sheets, metal sheets, polymer films, etc.

2)Lab Film Applicators Spreader Coatings evenly on the substrate surface by various coating methods. Common coating methods include:

Manual Spreader: Spreader the substrate surface by hand lame plating, roller coating or brushing.

Automatic Spreader: Some Advanced Laboratory Film Applicators are equipped with an automatic Spreader system, which can achieve automatic Spreader, improve experimental efficiency and Spreader uniformity.

3) After the Spreader is completed, the substrate needs to be dried curing to form a stable structure of the coating. This is usually achieved by heating, ventilating or ultraviolet curing.

4)After the drying curing is completed, researchers can perform various characterization analysis on the coating, such as thickness measurement, surface topography observation, mechanical properties testing, etc., to evaluate the performance and application potential of the coating.

Laboratory Film Applicators have a wide range of applications in the field of scientific research, mainly reflected in the following aspects:

New material research: Laboratory Film Applicators can be used to study the Spreader performance and application potential of various novel Coatings, Nanomaterials or Functional Materials, and provide technical support for the development and application of New materials.

Functional coatings research: Through the laboratory Film Applicator, coatings with specific functions can be prepared, such as anti-corrosion coatings, antibacterial coatings, Optical inspection coatings, etc., to study their application effects in different fields.

Thin film electronic device prepative: Laboratory Film Applicators can be used to prepare key components of thin film electronic devices, such as organic solar cells, flexible displays, flexible Sensors, etc., to provide technical support for research and application in the field of flexible electronics.

Biomedical applications: Laboratory Film Applicators can be used for preparing coating materials in the field of Biomedical, such as drug carriers, tissue engineering scaffolds, etc., to provide technical support for research and application in the field of Biomedical.

As an important experimental equipment, laboratory Film Applicator plays an important role in the field of scientific research. Through Spreader experiments on different materials, researchers can deeply understand the performance and application of coatings, and promote research and development in related fields. It is believed that with the continuous advancement of science and technology, laboratory Film Applicator will demonstrate its important value in more fields.