In today's rapidly developing technology field, Film Applicator is a key production equipment, widely used in various fields, including but not limited to Encasement, printing, electronics, medical, etc. It is crucial to choose a Film Applicator that suits your needs, not only to improve production efficiency, but also to ensure product mass. This article will explain how to choose the Film Applicator that suits your needs.

Before choosing a Film Applicator, you first need to clarify your film requirements. Factors you need to consider include:

Spreader Material: Is the material type you need for Spreader semi-solid or liquid? What is the viscosity and flowability of the Spreader material?

Spreader Thickness: What is the Spreader thickness you need to achieve? Can the coater meet your Spreader thickness requirements?

Spreader Area: What is the area size of the Spreader you need? Is the application width of the Film Applicator sufficient?

涂布速度:您需要的生产速度是多少?涂膜机的涂布速度是否能够满足您的需求?

Depending on the film Applicator's coating method and Spreader material, Film Applicators can be classified into various types, including:

Roller Film Applicator: Use roller to evenly Spreader the Coating on the substrate surface, suitable for liquid Coatings and flexible substrates.

Spray Coating Machine: Spray the coating on the surface of the substrate through Nozzle, suitable for liquid and solid coatings.

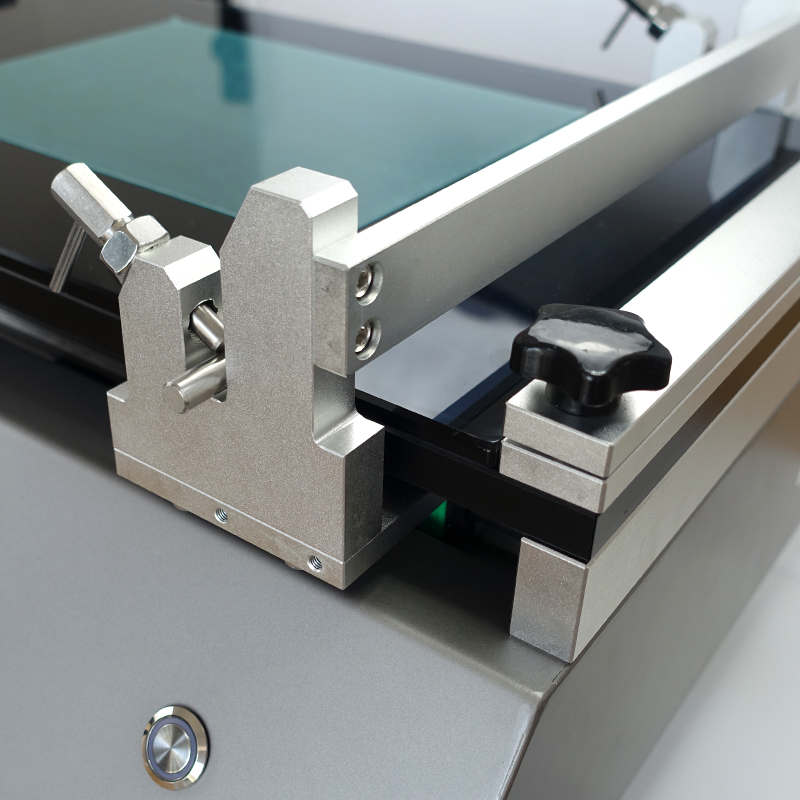

Spin coating machine: Coating Spreader on the surface of the substrate using spin coating roller or drawdown blade, suitable for high viscosity Coatings and special Coatings.

Depending on your film needs and the characteristics of the Spreader material, it is important to choose the type of Film Applicator that is right for you.

When choosing a Film Applicator, the mass and performance of the equipment are crucial factors. You need to consider the following aspects:

Equipment Brand and Reputation: Selecting a well-known brand of Film Applicator usually guarantees the mass and Stability of the equipment.

设备性能指标:包括涂布速度、涂布厚度控制精度、涂布均匀性等,需要根据您的需求进行评估。

设备可靠性和耐用性:考虑设备的使用寿命和维护保养成本,选择耐用性和可靠性较高的涂膜机。

Before purchasing Film Applicator, it is important to understand the after-sales service and technical support provided by the equipment vendor. You need to consider the following:

After-sales service: Including equipment installation and commissioning, training, Maintenance and other services, you need to ensure that the supplier can respond and solve your problems in a timely manner.

技术支持:供应商提供的技术支持是否及时、专业?是否能够为您提供技术咨询和解决方案?

Finally, consider the price, performance, mass and After-sales service of the Film Applicator to choose the most cost-effective Film Applicator. Don't just look at the price and ignore the mass and performance of the equipment.

Selecting a Film Applicator that fits your needs is a complex and important task. By taking into account factors such as film requirements, Film Applicator type, equipment mass and performance, After-sales service and support, and cost and price performance, you will be able to find the best Film Applicator for you, increasing production efficiency and ensuring product mass.