This paper discusses the application technology of laboratory coater in film coating epoxy polyester. First, the characteristics of epoxy polyester and its wide application in different fields are introduced. Then the principle and structure of laboratory coater, as well as its advantages and application methods in film coating are discussed in detail. Finally, the importance and future development direction of laboratory coater in film coating epoxy polyester are summarized.

Epoxy polyester is an important polymer material with excellent physical and chemical properties, and is widely used in Coating, Adhesive, Composite and other fields. In these applications, film coating technology is one of the key steps to uniformly coat epoxy polyester on the surface of the substrate. As a precision coating equipment, laboratory coater plays an important role in film coating. This paper will focus on the application technology of laboratory coater in film coating epoxy polyester.

Features: Epoxy polyester has excellent heat resistance, corrosion resistance and Mechanical Properties, good bonding force and electrical insulation performance, so it is widely used in Coating, Composite, Adhesive and other fields.

Application: When epoxy polyester is used as a Coating, it can form a strong coating to protect the surface of the substrate from chemical corrosion and mechanical abrasion; in composites, it can enhance the strength and stiffness of the material; in Adhesives, it can achieve bonding of various materials.

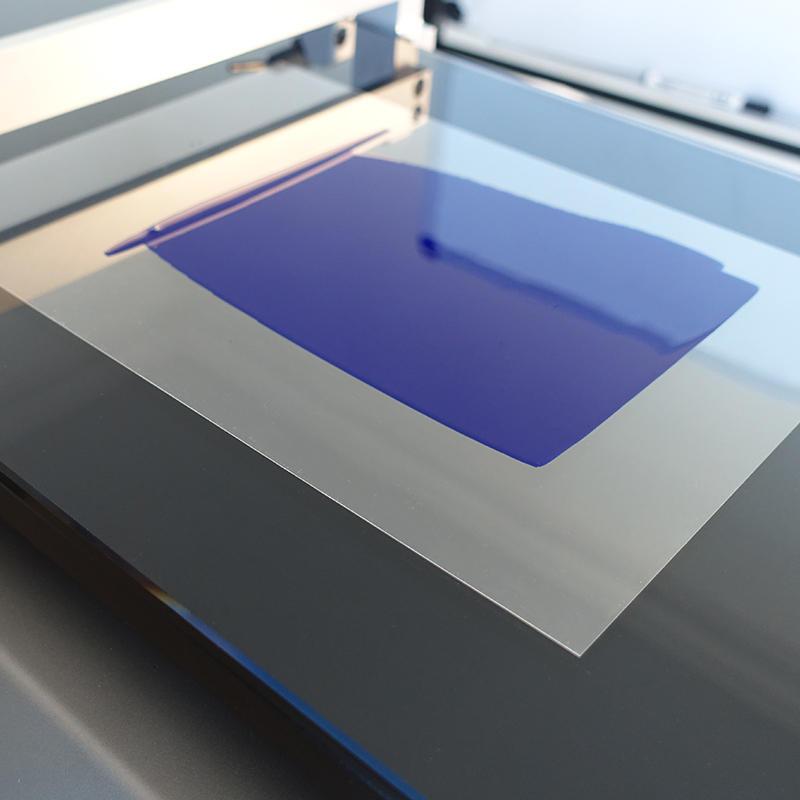

A laboratory coater is a device used for coating liquid materials on the surface of a substrate. Its Working Principle mainly includes key components such as Spreader rollers, pressure rollers, and substrate rollers. Spreader rollers are responsible for uniformly coating liquid materials on the surface of the substrate. Pressure rollers are used to control the thickness of Spreader, while substrate rollers drive the movement of the substrate. Laboratory coaters usually have adjustable working parameters such as Spreader speed, pressure, and temperature to meet the coating requirements of different materials.

Advantage:

Precision control: The laboratory coater has highly adjustable coating parameters, which can precisely control the thickness and speed of the Spreader to ensure the Stability of the coating mass.

Efficient performance: The laboratory coater has high coating speed and production efficiency, suitable for small batch production and R & D testing.

Flexibility: The laboratory coater can be adjusted according to the requirements of different materials and is suitable for coating various types of liquid materials.

Application method:

Adjust Spreader parameters: According to the properties of epoxy polyester and coating requirements, adjust the parameters such as Spreader speed, pressure and temperature of the laboratory coater.

Optimization of Spreader process: Through testing and adjustment, the Spreader process is optimized to make the coating uniform and stable, and meet the expected performance requirements.

Detection and analysis: Detection and analysis of the coated film to evaluate its physical performance and chemical performance, to provide reference for product mass improvement.

Laboratory coaters have important application value and development prospects in film coating epoxy polyester. With the continuous progress of science and technology, the performance of laboratory coaters will be further improved, and the coating process will be more precise and efficient. In the future, we can expect laboratory coaters to play a greater role in the field of epoxy polyester coating and promote the progress and innovation of related technologies.

This article discusses the application technology of laboratory coater in film-coated epoxy polyester, and elaborates in detail from the characteristics and applications of epoxy polyester, the principle and structure of laboratory coater, to the advantages and application methods, providing reference and reference for research and application in related fields.