In this paper, the process and effect of coating silicone on polyethylene terephthalate (PET) substrate by Automatic Film Applicator were studied. Through systematic experiments and Data analysis, the effects of film speed, film thickness, stoving temperature and other parameters on coating mass were discussed. The results show that the optimized film process can significantly improve the uniformity and adhesion of coatings, providing reliable technical support for the application of PET substrates in the fields of electronics and Optical inspection.

PET is a high-performance polymer material with excellent mechanical strength, transparency and chemical resistance, so it is widely used in Encasement, Electronics, Optical inspection and other fields. In order to further expand the Application of PET substrates and improve their surface performance, it is usually necessary to functionalize their surfaces. Silicone materials are ideal for surface modification of PET substrates due to their excellent heat resistance, weathering resistance and low surface energy.

Automatic Film Applicator, as an efficient and accurate Spreader device, can achieve precise control of Coating thickness and automation of Spreader process, and is suitable for large-scale production. The purpose of this study is to use Automatic Film Applicator to coat silicone on PET substrates, explore the impact of its process parameters on coating performance, and then provide guidance for actual production.

Substrate: PET film with a thickness of 100 microns.

Coating: silicone coatings, the main component is polydimethylsiloxane.

Equipment: Automatic Film Applicator TM3300 with adjustable film speed, film thickness and stoving temperature.

Substrate treatment: cut the PET film into a size of 10cm × 10cm, wash it with ethanol to remove surface dirt and grease, and dry it for later use.

Film process:

Film speed: set to 10mm/s, 20mm/s, 30mm/s.

Film Thickness: Adjust the blade height of the Film Applicator to 5 microns, 10 microns, and 15 microns respectively.

Stoving temperature: set to 60 ℃, 80 ℃, 100 ℃.

Test method:

Coating thickness: laser thickness measurement.

Coating uniformity: observed by Optical Microscopy.

Adhesion testing: 100 grid test.

The experimental data were analyzed by Excel and Origin software, and the Linear dispersion diagram of the influence of each parameter on the coating performance was drawn.

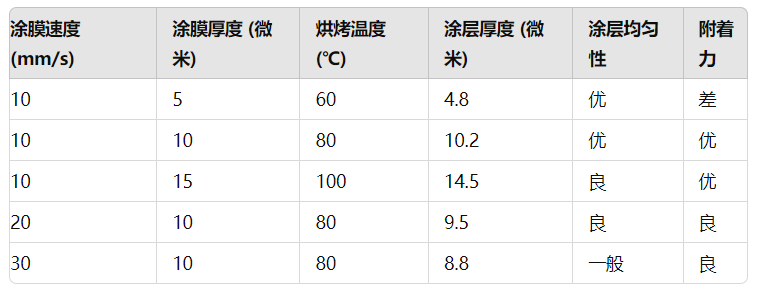

It is found that the film speed has a significant effect on the thickness and uniformity of the coating. When the film speed is low (10mm/s), the coating is thicker and has better uniformity; with the increase of speed, the Coating thickness gradually decreases, but the uniformity decreases. This is because at higher speeds, the Coating does not spread on the surface of the substrate for enough time, resulting in uneven coating.

Coatings at different film thicknesses exhibit different performance. When the film thickness is 5 microns, the coating is thinner and has better uniformity, but poor adhesion; when the thickness is increased to 10 microns, the coating adhesion is significantly improved, and the uniformity is still good; when it continues to increase to 15 microns, the coating uniformity decreases, but the adhesion is optimal. This indicates that moderate film thickness contributes to the uniformity and adhesion of the equilibrated coating.

The stoving temperature has an important impact on the degree of curing and adhesion of coatings. Experimental results show that at lower stoving temperatures (60 ° C), the coating curing is not complete and the adhesion is poor; as the temperature increases, the coating is gradually cured completely, and the adhesion is significantly improved. When the temperature reaches 80 ° C, the coating performance is the best; when it continues to rise to 100 ° C, the coating performance does not further improve, and there is a risk of thermal deformation of the substrate.

Through the analysis of the above experimental results, the optimized film process parameters are: film speed 10mm/s, film thickness 10μm, stoving temperature 80 ℃. Under this condition, the coating has the best uniformity and adhesion, which can meet the practical application requirements. In addition, the process Stability and equipment maintenance in actual production need to be considered to ensure the continuous stability of the coating mass.

In this study, the influence of the process parameters of Automatic Film Applicator coating silicone on PET substrate on coating performance was investigated through systematic experiments. The results show that film speed, film thickness and stoving temperature are the key factors affecting the coating mass. The optimized film process parameters are film speed 10mm/s, film thickness 10μm, stoving temperature 80 ℃, under which the coating has the best uniformity and adhesion.

This study provides a technical reference for the surface functionalization of PET substrates, which has important application value and promotion prospects. Future research can further explore different silicone materials and film processes to expand the application range of PET substrates and improve their comprehensive performance.