Film technology is widely used in modern industry, among which the film on Plastic film is particularly important. PET (polyethylene terephthalate) films are widely used in Encasement, Electronics, Optical inspection and other fields due to their excellent Mechanical Properties, transparency and chemical resistance. Film Applicator, as the core equipment of Spreader technology, has a direct impact on the uniformity, thickness control and coating performance of films. This experiment aims to explore the process and effect of coating Stock on PET films with small Film Applicator, and provide reference for related industrial applications.

Small Film Applicator: Key equipment for controlling Stock Uniform Spreader with speed regulation and precision Spreader head.

Drying equipment: Used to accelerate Stock curing and ensure film mass.

Thickness gauge: used to measure film thickness to ensure film uniformity.

Microscope: used to observe film surface morphology and evaluate film mass.

PET film: thickness of 50μm, width of 300mm.

Spreader Stock: A composite of gluing agents, fillers and solvents.

Cleaner: Used to clean equipment and substrate surfaces.

Use detergent to thoroughly clean the surface of PET film to remove impurities such as grease and dust to ensure film adhesion.

Configure Spreader Stock as needed, adjust the viscosity of Stock, Solid content and other parameters to make it suitable for Spreader process.

Adjust Film Applicator Speed, Pressure and Spreader Head Height to ensure uniform Spreader.

Place the cleaned PET film on the film machine, start the device, and start the Spreader. Keep the Film Applicator speed constant to ensure that the Stock is evenly Spreader on the film surface.

After the Spreader is completed, the PET film coated with Stock is placed in the drying equipment to control the temperature and time, so that the Stock is completely cured.

Thickness measurement: Use a thickness gauge to measure film thickness, record data, and analyze film uniformity.

Surface observation: Microscope is used to observe the surface topography of the film and check for defects such as bubbles and particles.

Adhesion testing: Evaluate the adhesion of the film to the PET film through tensile testing to ensure the firmness of the film.

Film thickness analysis

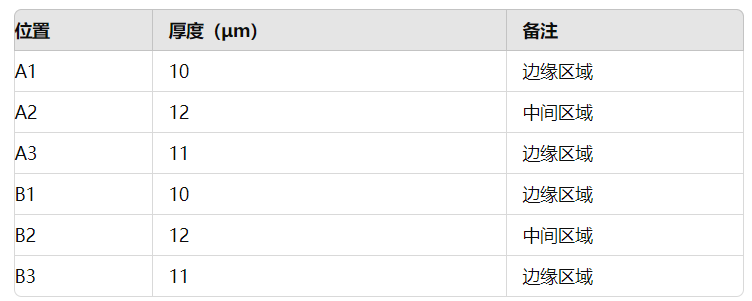

The film thickness data obtained by thickness gauge measurement are shown in Table 1:

Analysis of the data shows that the film thickness is between 10-12 μm, which is basically uniform, but the edge area is slightly thin. This may be due to the uneven pressure distribution of the Film Applicator Spreader head. Optimizing the Spreader head design or adjusting the Spreader parameters can improve this problem.

Surface topography observation

Microscope observation of the film surface morphology is shown in Figure 1. The film surface is smooth, without obvious bubbles and particles, indicating that the Spreader process and Stock formulation are ideal. However, at high magnification, it is found that there are tiny crazing and Holes on the film surface, which may be caused by excessive heating during drying. This defect can be reduced by appropriately lowering the drying temperature or prolonging the drying time.

adhesion testing

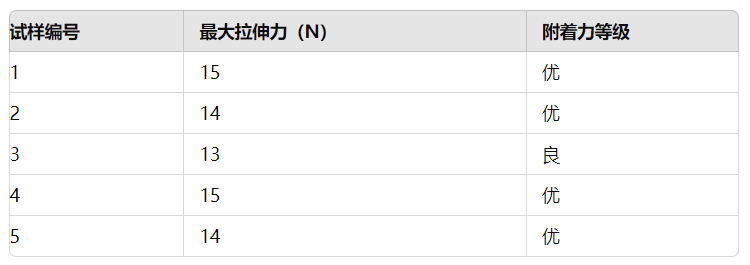

The film adhesion testing results are shown in Table 2:

The results show that the film and PET film have good adhesion, and the film is not easy to disbond, which meets the requirements of industrial application.

Through the experiment of Small Film Applicator Coating Stock on PET film, we got the following conclusions:

Film Applicator can achieve uniform Spreader of Stock, but there is a problem of uneven thickness in the edge area, which requires optimizing the design of the Spreader head or adjusting the Spreader parameters.

The film surface is smooth without obvious defects, but there are tiny crazing and holing at high magnification, which can be improved by optimizing the drying process.

The film and PET film have good adhesion and meet the requirements of industrial applications.

This experiment provides an important reference for the application of Small Film Applicators on PET films. Further optimization of process parameters and equipment design can improve film mass and meet higher industrial requirements.