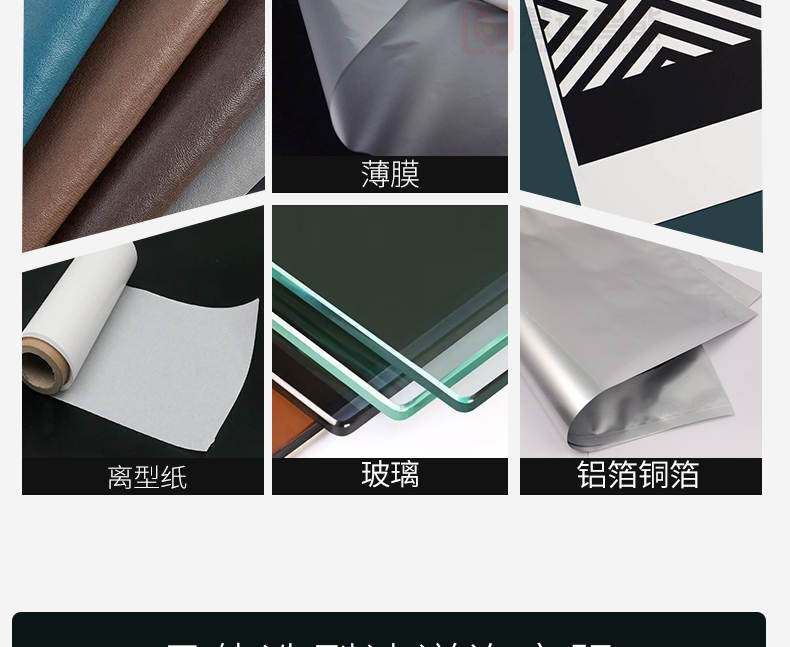

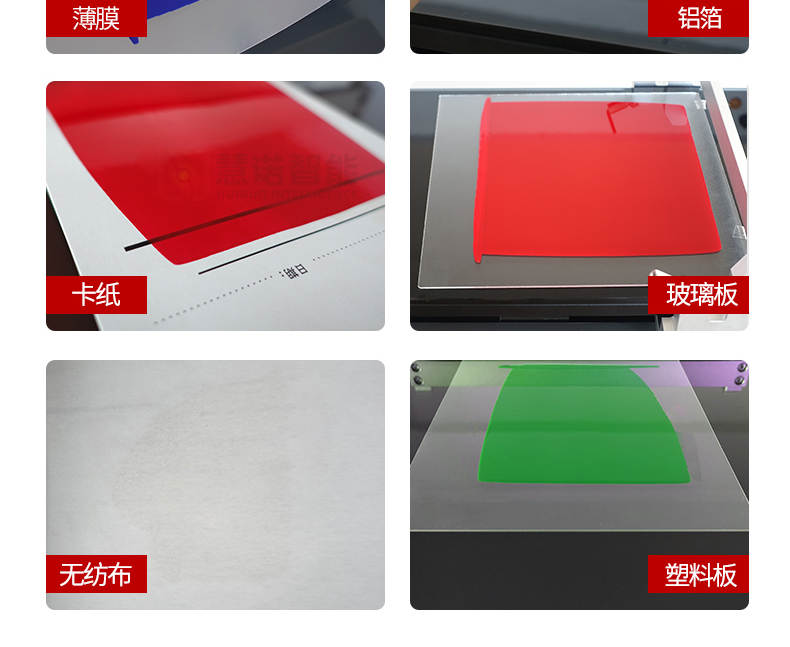

Automatic Film Applicator is a device used for intermediate coating film in laboratory. It replaces manual film and automatically films to improve the accuracy and efficiency of film. The Working Principle of Experimental Automatic Film Applicator is to uniformly Spreader the sample on the substrate by controlling the Spreader head and Spreader parameters to form the desired film.

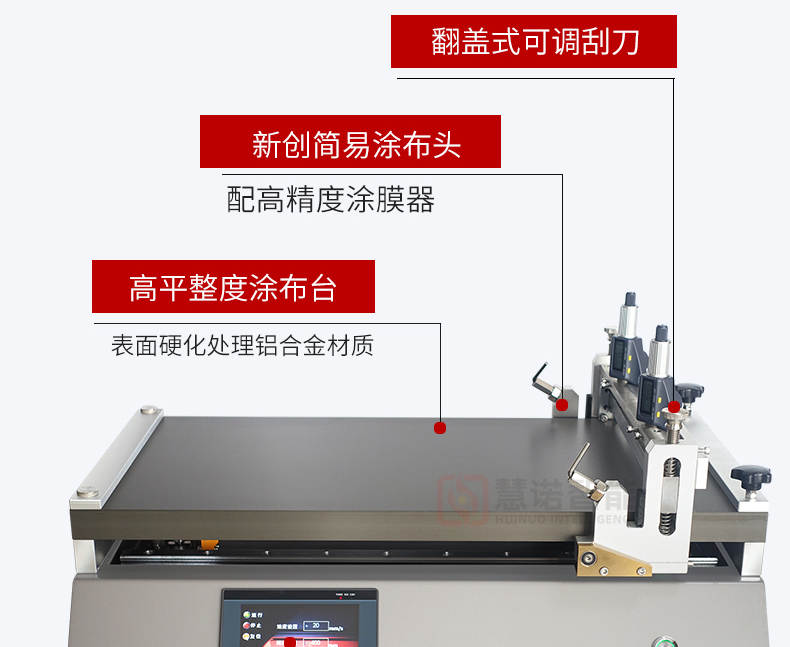

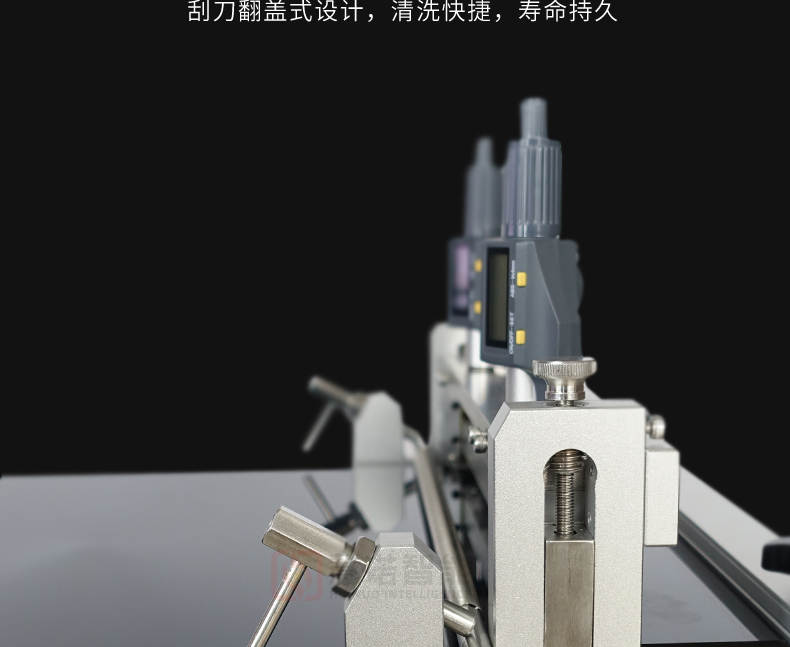

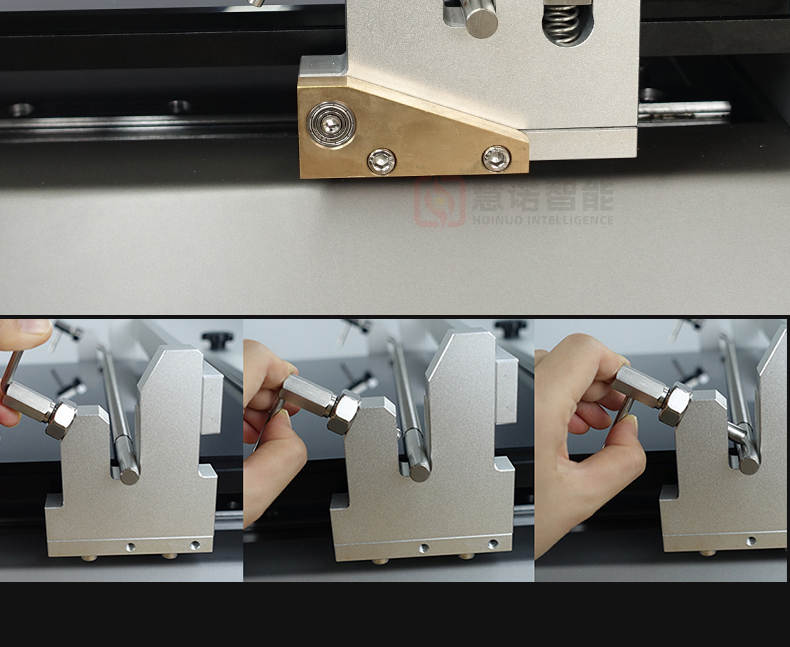

TM1300 bar heating Vacuum chuck Film Applicator uses bar coating method, accuracy up to 1μm, with heating and Vacuum chuck function, bar adopts snap-on design, simple installation to reduce abrasion, suitable for laboratory High Accuracy automatic film, Moulding proofing in laboratories such as university research institutes, New material, plaster, Coating inks, film, lithium battery Stock, etc.

| Model | TM3100 |

| coating method | Bar Spreader |

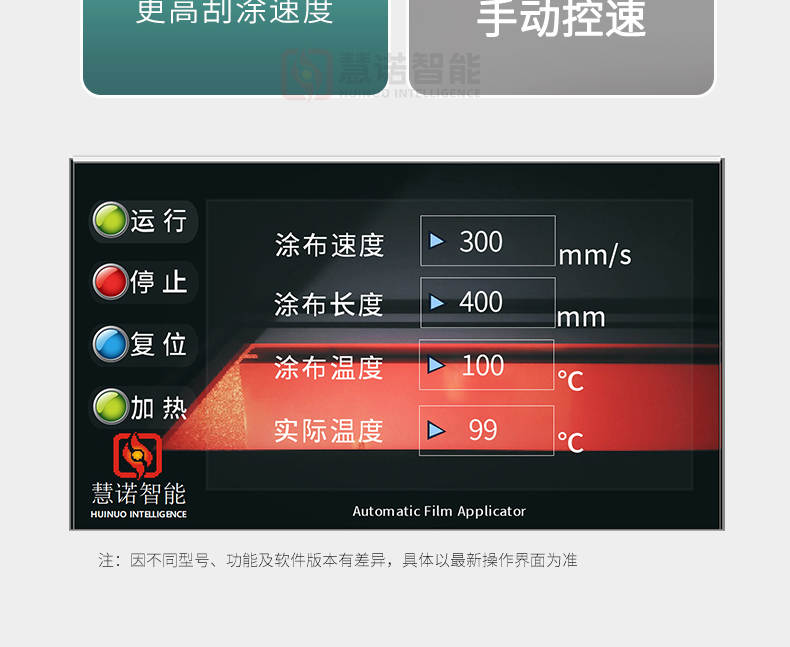

| Spreader speed | 5~ 250Mm/s stepless speed regulation (can be customized) |

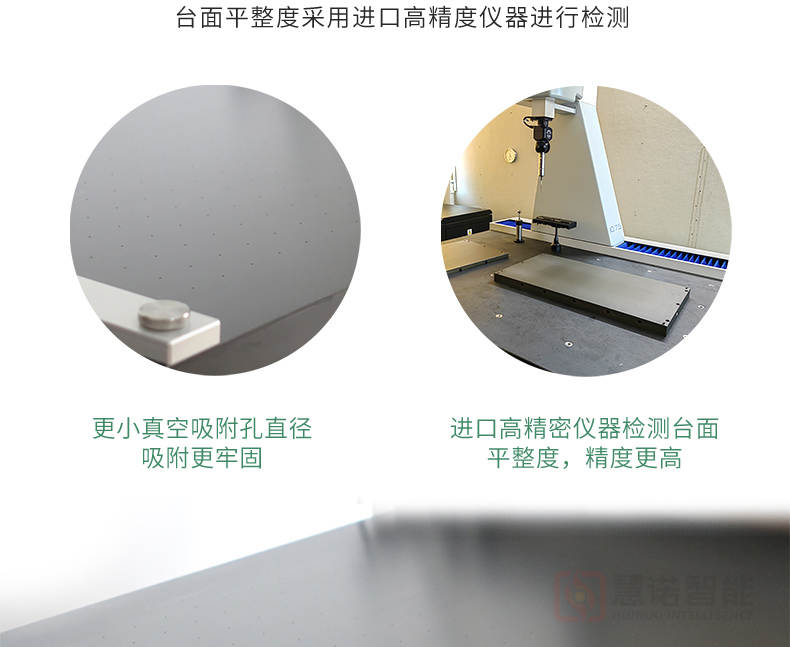

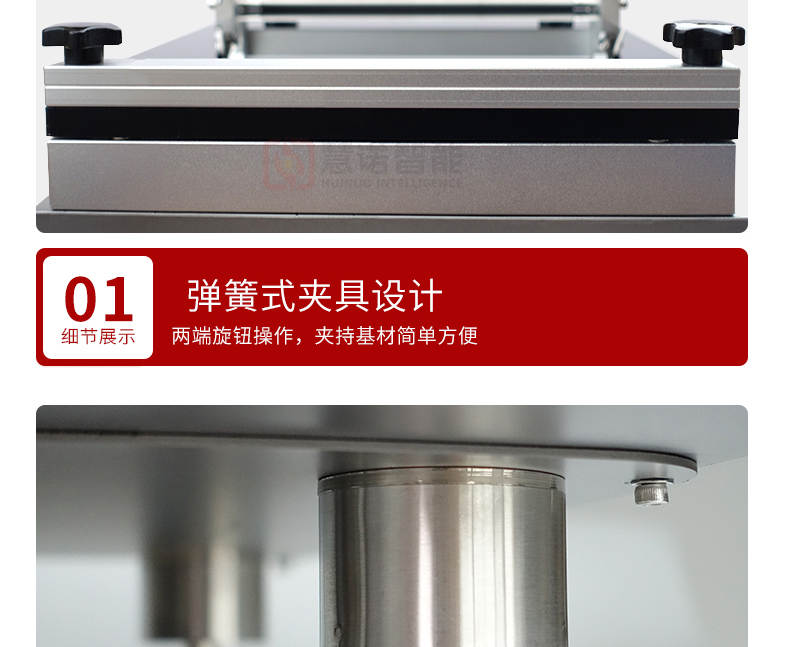

| Substrate fixing method | Vacuum chuck + fixture |

| Spreader Platform | Surface hard treatment aluminum alloy |

| Spreader Platform size | 300mmx600mm |

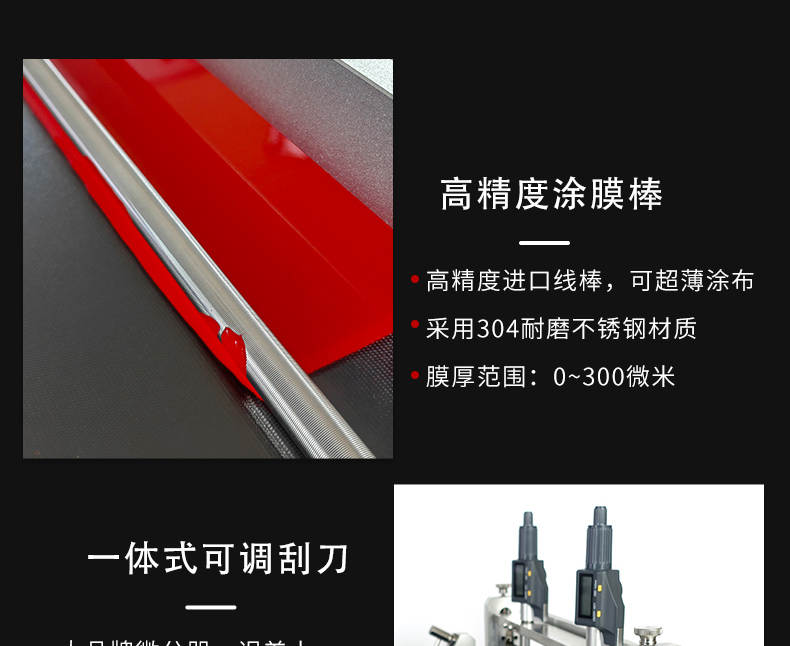

| Film thickness | Controlled by bar with High Accuracy import bar |

| Bar film accuracy | ±0.001mm |

| effective coating area | 300Mm * 400mm (can be customized) |

| Heating temperature | RT+~180°C |

| Temperature Uniformity |

±3℃ |

| Vacuum Area | 300 * 400Mm (can be customized) |

| Vacuum aperture diameter | φ0.8mm |

| Vacuum hole pitch | 20*20mm |

| display screen | Color LCD Touchscreen |

| Host power supply | 220V 50HZ |

| Dimension | 658mm*438mm*400mm(L*W*H) |

| Power | 1800w |