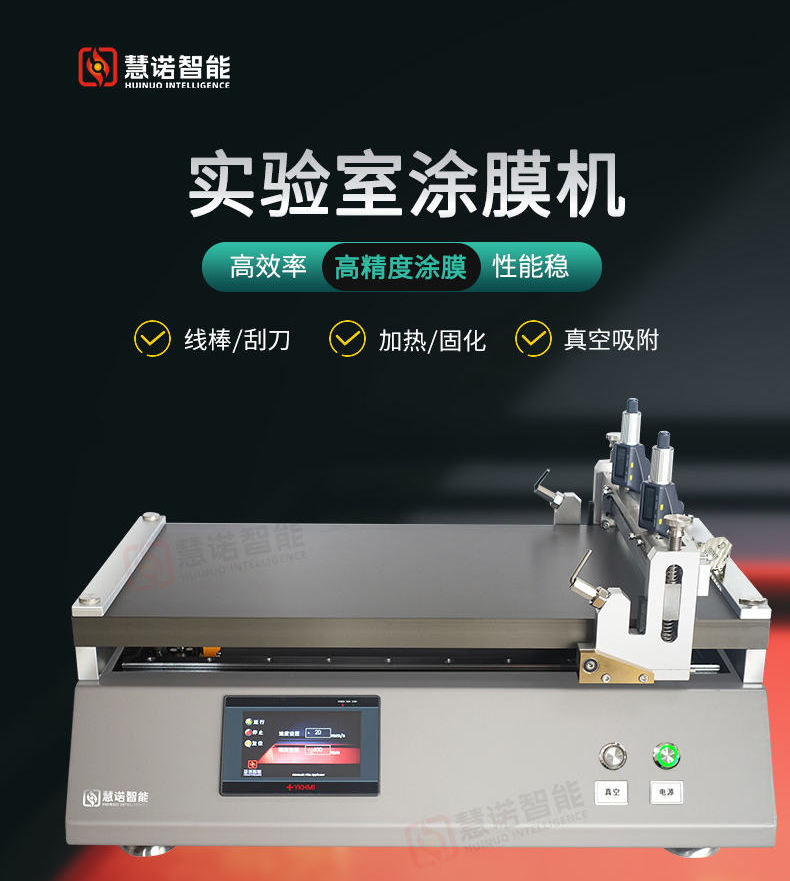

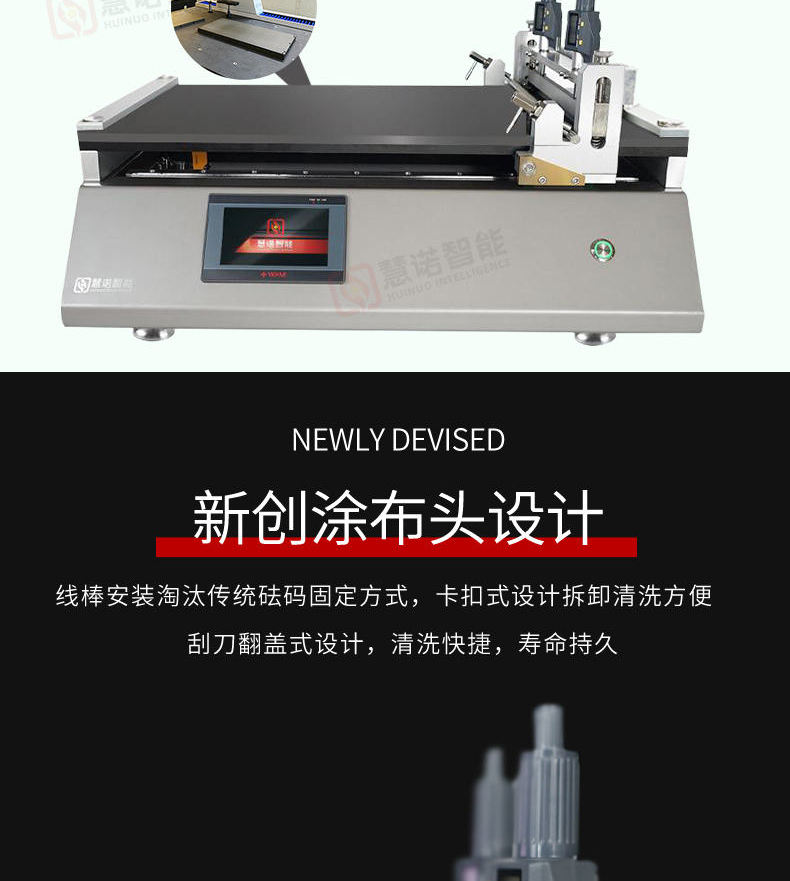

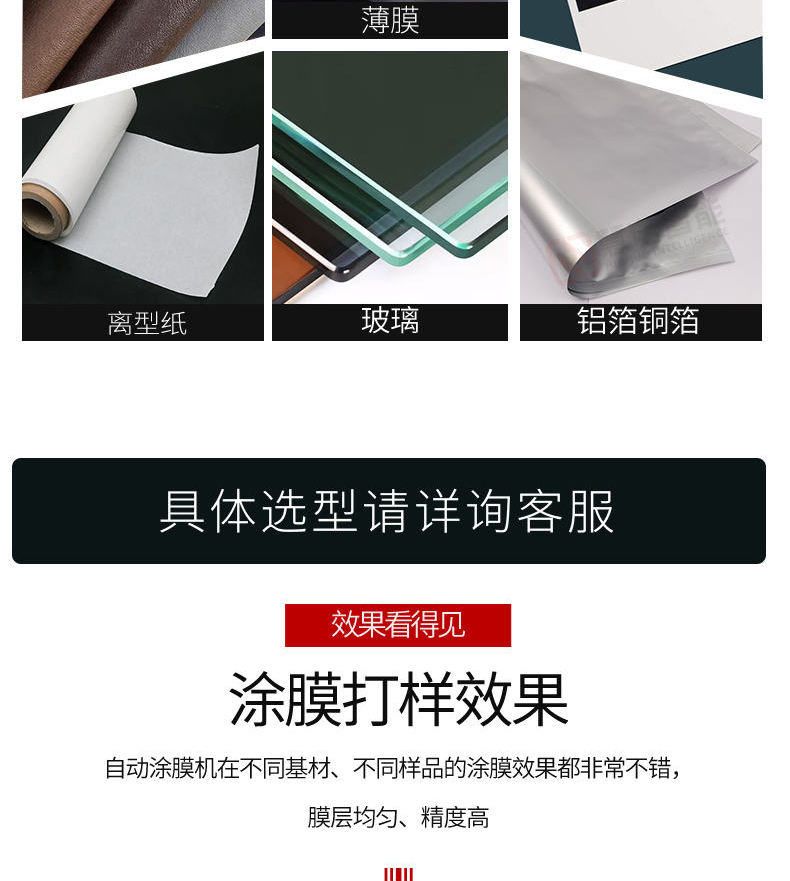

The core selling point of HuiNuo TM3200AF/09D Floor-Standing Multifunctional Film Applicator is its high degree of automation and excellent Stability. It integrates bar, Blade Coating and standard automatic feeding system to realize the whole process automation from Spreader to Feed, effectively improving efficiency and ensuring film conformity. The equipment adopts the dual Vacuum chuck and fixture Substrate clamping method, especially the Vacuum chuck function ensures the smooth and flawless large-size film Spreader. Its servo motor drive and High Accuracy processing ensure the stability of the Spreader process, with an accuracy of +/- 0.003mm, while the 1L volume pressure stainless steel and Mixing Tank meet the needs of continuous production. It is a fully automatic film equipment for high-end laboratories and small batch precision production.

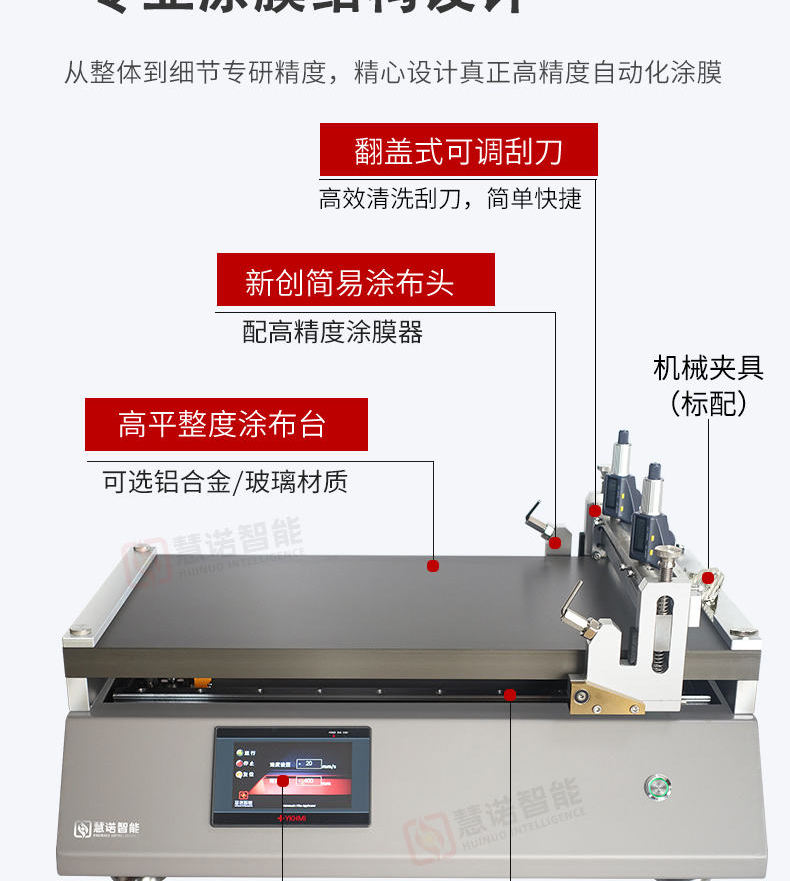

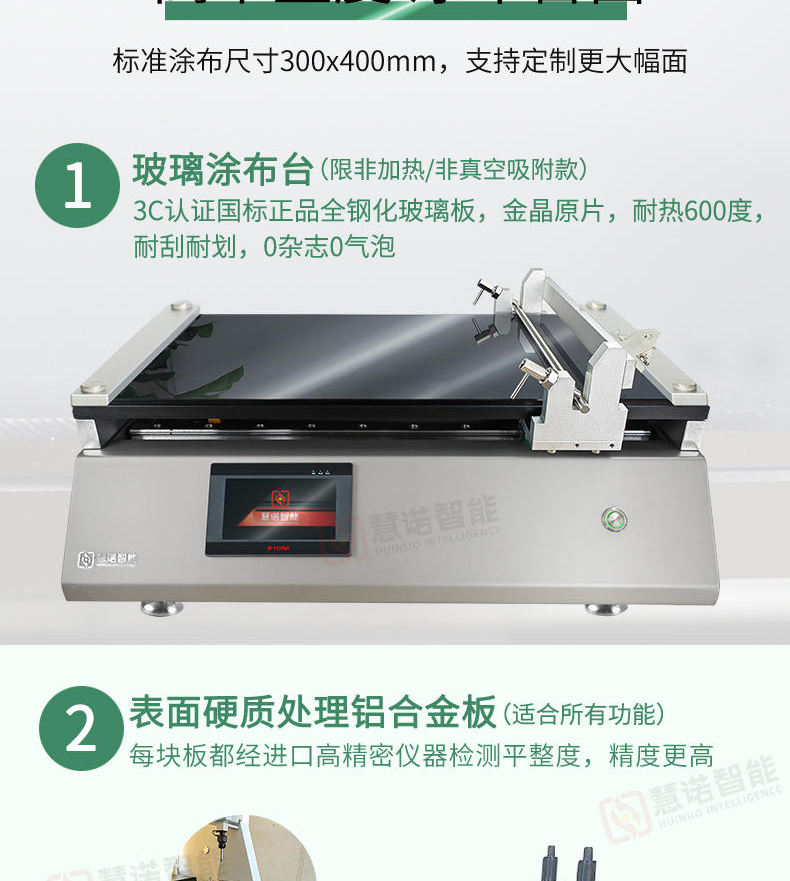

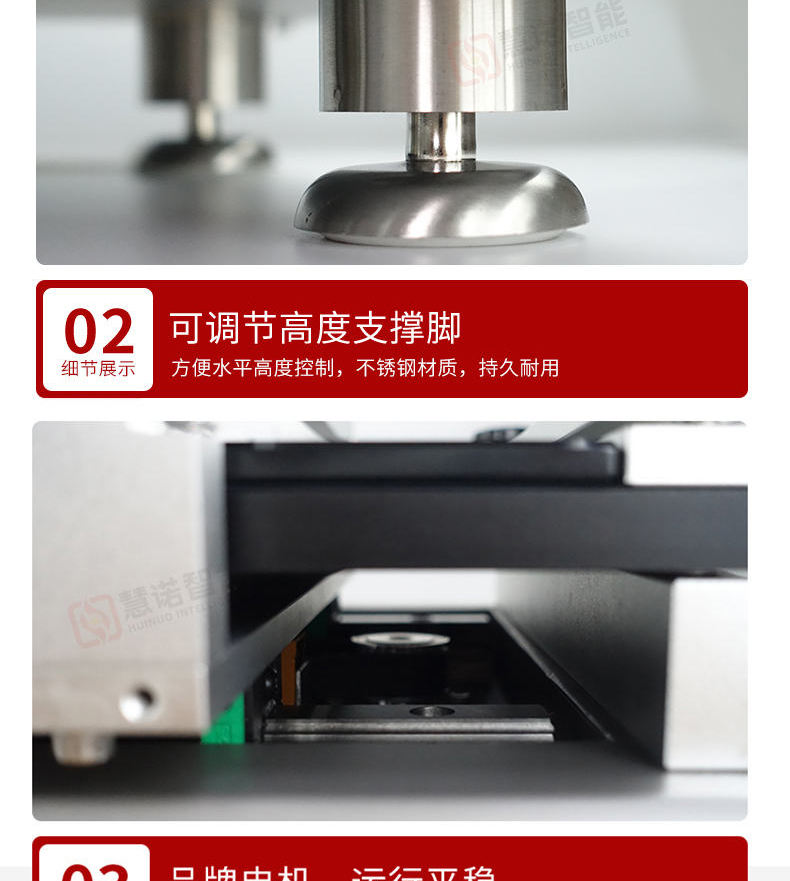

1) Surface Hard Treatment Aluminum Alloy Table, Hardness High Wear Resistance, Table Smoothness Imported High Accuracy Instrument for Testing

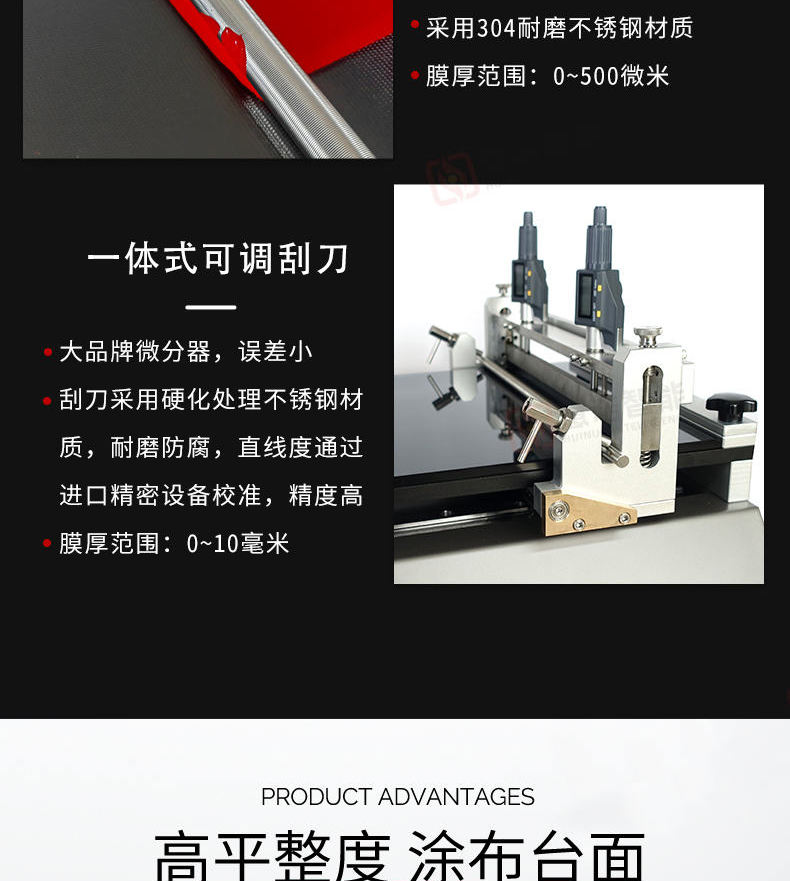

2) Big brand differential regulator, high film thickness control accuracy

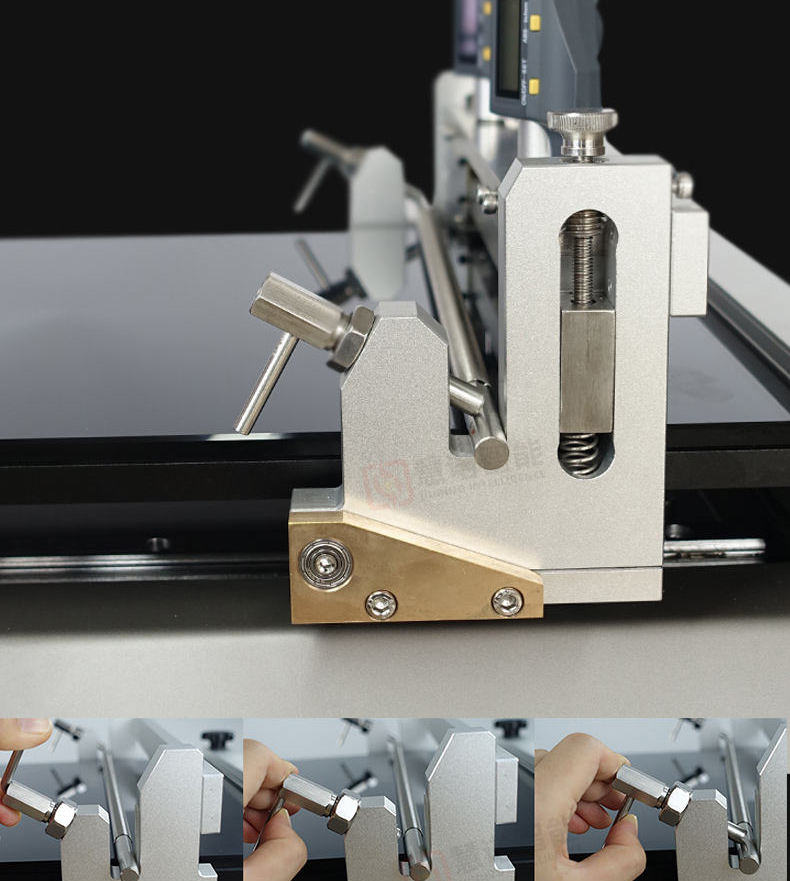

3) Flip Type Blade Coating Head for Easy Cleaning

4) High Accuracy film applicator with high accuracy of original imported bar film

5) Touchscreen control panel, easy to operate

6) Free adjustment of application length and Spreader speed

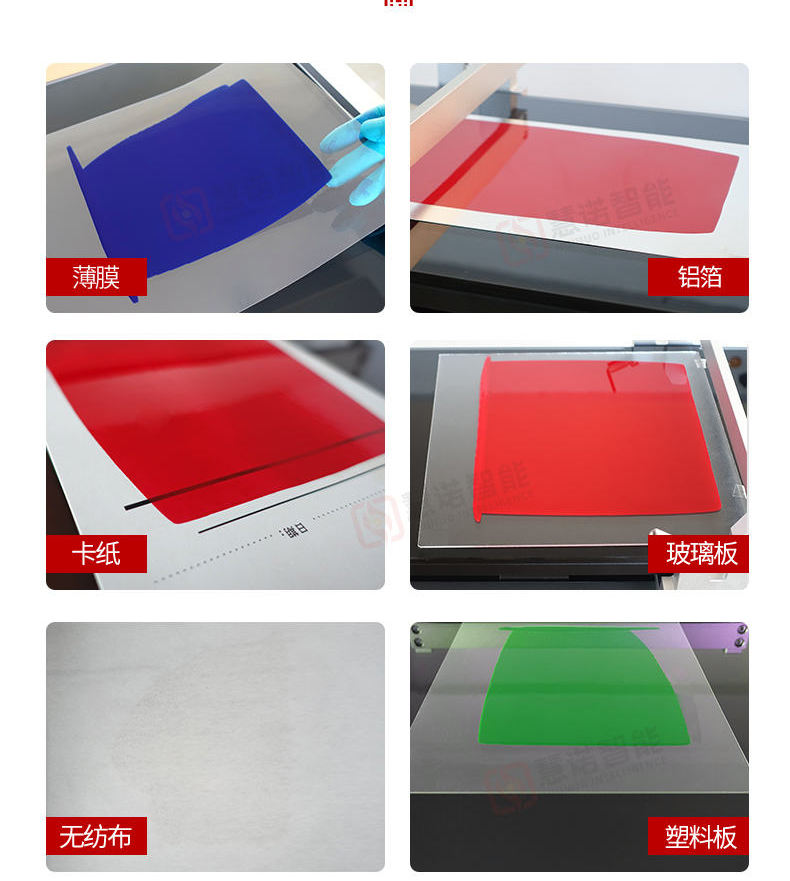

7) With Vacuum chuck function, suitable for thin film and other soft substrate Spreader

Model |

TM3200AF/09D |

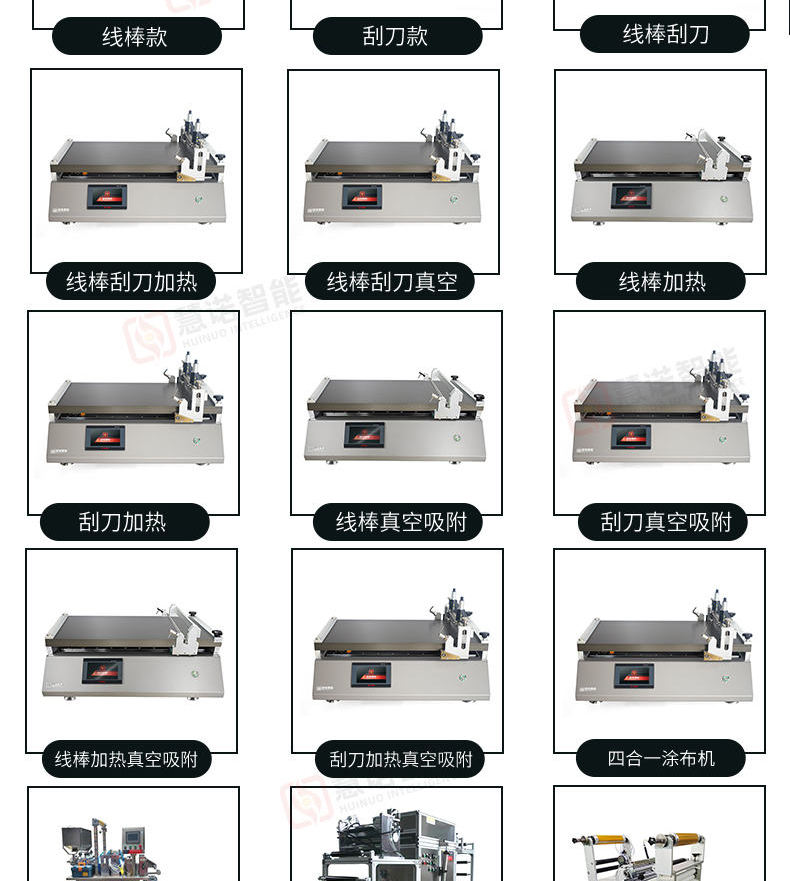

coating method |

Bar + drawdown blade |

coating speed |

1~ 300Mm/s stepless speed regulation (can be customized) |

Substrate clamping method |

Vacuum chuck + fixture |

Coating table material |

Surface hard treatment aluminum alloy |

effective coating area |

700 * 800Mm (can be customized) |

Spreader Platform size |

940*830mm |

meyer rod coating thickness range |

Different bar sizes have different thicknesses, with High Accuracy imported bars |

meyer rod coating accuracy |

±0.003mm |

Blade Coating Thickness Range |

0.1~ 10Mm (clamshell design is easy to clean) |

Drawdown blade material |

Die steel |

Blade Coating Width |

800mm |

Blade Coating accuracy |

±0.003mm |

Vacuum Area |

780 * 760Mm (can be customized) |

Vacuum aperture diameter |

Φ0.8mm |

Vacuum hole pitch |

20*20mm |

Drive motor |

Servo motor |

Vacuum pump pumping rate |

5.4m3/h |

Ultimate vacuum degree |

50KPa |

Power |

600w |

Vacuum Pump Power |

180W |

Vacuum pump weight |

7.1kg |

Operating language |

Chinese (can be customized in English) |

standard feature |

Automatic inking system |

Feeding principle |

Air source pressure flows out |

Feed Sport Mode |

Reciprocating linear motion |

Feeding back and forth traverse speed |

2~150mm/s |

spit volume |

Adjustable (by adjusting the air pressure and the running speed of the discharge port) |

Shaft transmission mode |

timing belt |

Feeding system air source |

0.6Mpa, which can be connected to the trachea of < unk > 8 (self-equipped). |

Power voltage of charging system |

220V,50Hz |

Mixing Tank Pressure |

Maximum withstand 8Mpa |

Mixing Tank Material |

304 stainless steel with a wall thickness of 4mm |

Mixing Tank Configuration |

Safety valve, pressure regulating valve, pressure gauge, discharge valve |

Mixing Tank Volume |

1L |

display screen |

Color LCD Touchscreen |

Host power supply |

220V/50HZ (can be customized 110V/60HZ) |

Dimension |

960*940*940mm |