With the rise of renewable energy and the rapid development of the electric vehicle market, lithium batteries have received extensive attention as a high energy density and environmentally friendly energy storage device. Stock coating of anode and cathode is a crucial step in the manufacturing process of lithium batteries. This article will explore the experimental application of Lab Film Applicator coating lithium battery stock on aluminum foil.

A lithium battery is a rechargeable battery that stores and releases energy by moving lithium ions between positive cathodes. In the manufacturing process of lithium batteries, the preparation of anode and cathode is one of the crucial steps. Coating positive cathode Stock is one of the key steps in the anode and cathode preparation process.

The purpose of this experiment is to uniformly coat the Stock of lithium battery anode or cathode on aluminum foil by using the Laboratory Film Applicator to simulate the actual process of lithium battery preparation and evaluate the film effect.

Preparation

Stock the required aluminum foil and lithium battery anode or cathode.

Clean the Spreader Head and Spreader Roller of the Lab Film Applicator to ensure no impurities.

Adjust the parameters of the Laboratory Film Applicator, such as Spreader Speed, Spreader Thickness, etc.

Coated Stock

Load the aluminum foil onto the laboratory film machine to ensure that the surface of the aluminum foil is smooth and tidy.

Stock of lithium battery anode or cathode is injected into the liquid supply system of the coater.

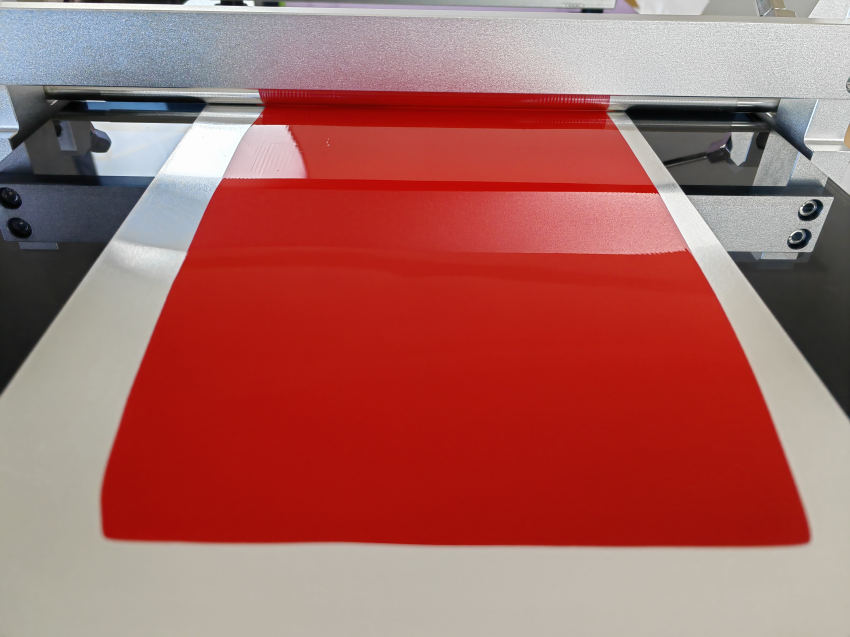

Start the Lab Film Applicator and Spreader the Stock evenly over the foil surface.

Drying treatment

After the coating is completed, the coated aluminum foil is sent to the drying chamber to volatilize the solvent in the Stock and curing Stock film formation.

According to the nature and requirements of the stock, set the appropriate drying temperature and time.

Evaluate film effects

The surface mass of the coated aluminum foil is checked, including the uniformity of the coating, Glossiness and asperity.

Coated aluminum foil performance testing, such as electrochemistry performance, Abrasion Resistance and electrical conductivity.

After experiments, we successfully used the laboratory Film Applicator to uniformly coat the Stock of lithium battery anode or cathode on the aluminum foil, and dried it to form a Stock curing film. After evaluating the film effect, it was found that the coated aluminum foil surface coating was uniform and smooth, with good Glossiness and asperity control. At the same time, the performance test results showed that the coated aluminum foil had good electrochemistry performance and conductivity, showing excellent Abrasion Resistance and Chemical Stability.

The experimental results show that the experimental application of Lab Film Applicator in coating lithium battery Stock on aluminum foil has good effect and potential. Efficient coating of positive cathode Stock of lithium battery can be achieved by reasonably adjusting Spreader parameters and process flow, which provides an important reference for the optimization and improvement of lithium battery prepative process. In the future, we will further study the application of Lab Film Applicator in lithium battery prepative process, explore more process parameters and coating technology, and make greater contributions to the development of lithium battery industry.